Product characteristics

1. Adopting self-made high-performance scanning motors and industry-leading optoelectronic sensing technology.

2. Using differential photoelectric sensors, it has good linearity, small drift, high resolution, and high repeatability positioning accuracy.

3. Adopting overload, overcurrent, and reverse protection design, the operation is more reliable.

4. Adopting electromagnetic compatibility optimization design, with high signal-to-noise ratio and strong anti-interference ability.

5. Adopting a diameter of 14mm lenses covering multiple wavelength ranges to meet the needs of various industries.

6. Compact in size, compact in design, and lightweight.

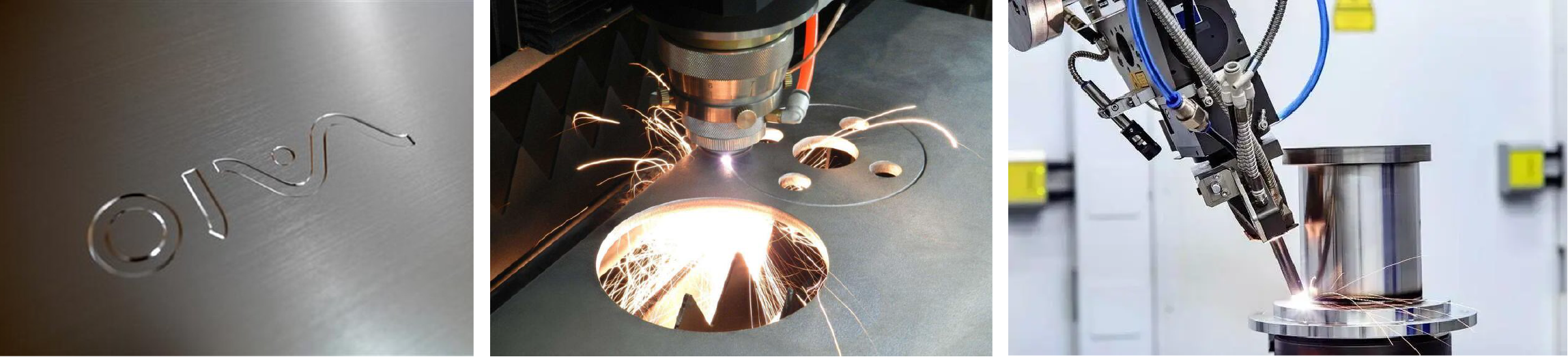

Product Application

Two-dimensional laser scanning galvanometer is widely used in laser etching, online flight marking, laser drilling, laser welding, laser cutting, additive manufacturing, 3D printing, medical beauty and other industries.

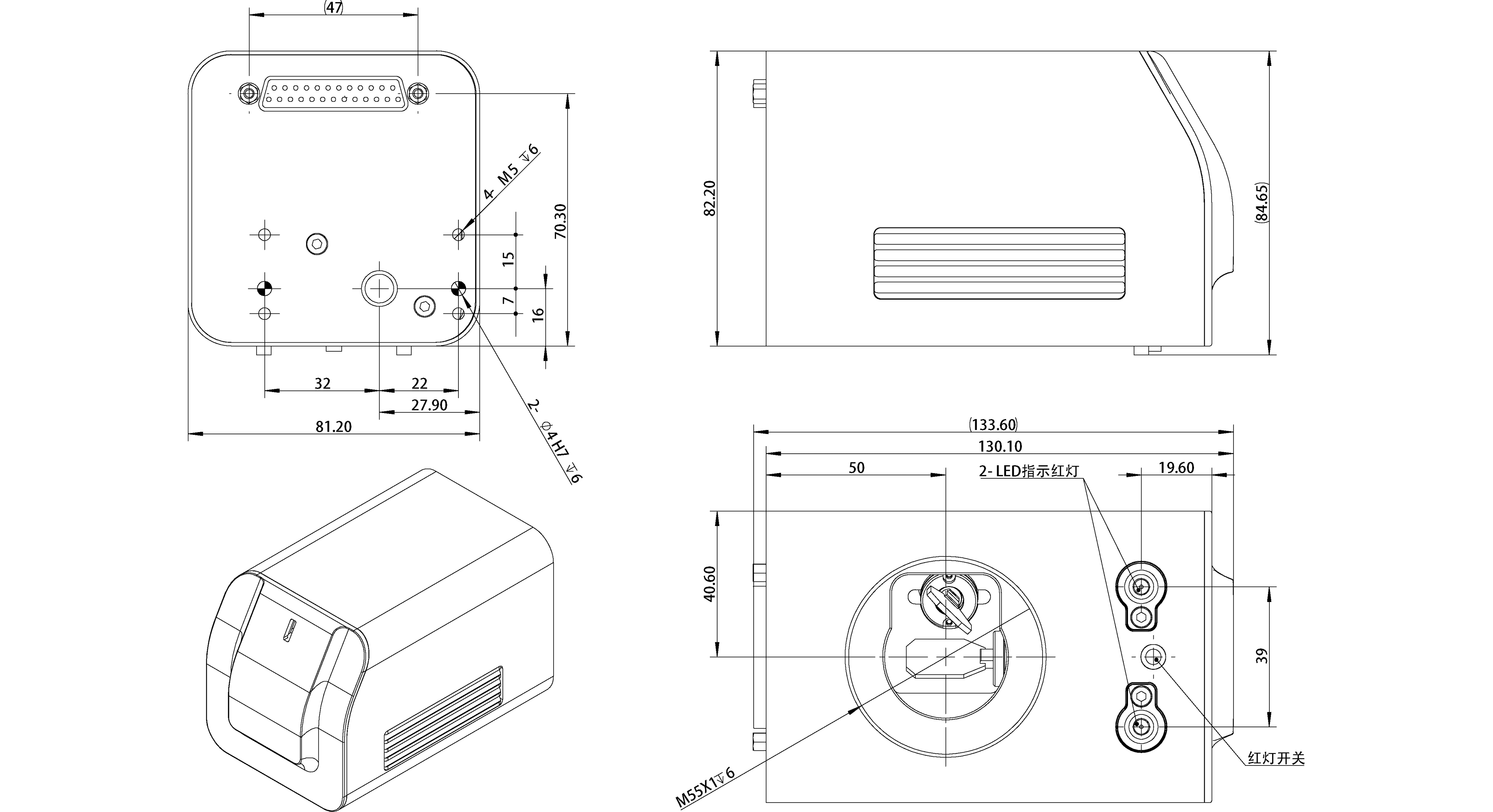

Product dimensions

Product performance parameters

| Dynamics 动态性能 | |

| Optical aperture 通光孔径 | Ф14mm |

| Tracking Error 跟踪误差 | <0.2 ms |

| Marking speed 打标速度 | 8.0 m/s |

| Positioning speed 定位速度 | 15.0m/s |

| Write speed 写入速度 | 600 cps |

| 1% full stroke step response time 1%满行程阶跃响应时间 | 0.4ms |

| 10% full stroke step response time 10%满行程阶跃响应时间 | 1.6ms |

| General parameters 通用参数 | |

| Power Supply 电源 | ±15VDC ,MAX 2A |

| Communication Protocol 通讯协议 | XY2-100 |

| IP rating IP等级 | IP65 |

| Working temperature 工作温度 | 0°c~45 °c |

| Storage temperature 存储温度 | -10 °c~60 °c |

| External dimensions 外形尺寸 | 149mm*107mm*113mm |

| Weight 重量 | <2.4kg |

| Accuracy and stability 精度及稳定性 | |

| Repetitive positioning accuracy (RMS) 重复定位精度(RMS) | <5 μ rad |

| resolving power 分辨率 | 16 bit |

| Nonlinearity 非线性度 | <0.9mrad/44° |

| Zero drift 零点漂移 | <30 μ rad/k |

| Gain drift 增益漂移 | <80 ppm/K |

| 8-hour long drift 8小时长时间漂移 | <0.3 mrad |

| Optical performance 光学性能 | |

| Scanning angle 扫描角度 | ±0.35 rad |

| Gain error 增益误差 | 5 mrad |

| Zero point error 零点误差 | 5 mrad |

Notes:

1. Use F-Theta field lens f = 163 mm / format size 120 mm x 120 mm;

2. 1mm High single stroke characters;

3. Stable at 1/1000 of the full stroke;

4. Optical angle. Drift of each axis, after 30 minutes of warm-up, the ambient temperature and processing load are stable.